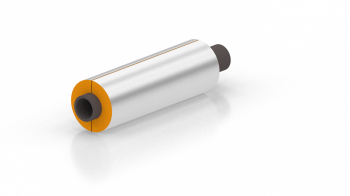

Resolution Phenolic PPS

(Pre-Formed Pipe Section 40kg/m3)

Accumen produces high-quality preformed pipe sections (PPS) using Austrotherm Resolution 40kg/m³ premium-performance phenolic foam, factory-faced with an aluminium foil vapour barrier. This product is among the most thermally efficient solutions for insulating pipework in building services and HVAC applications, capable of performing across an extensive temperature range from +120°C to -180°C. Resolution Phenolic PPS is free of chlorides and halogenated fire retardants, making it the ideal choice for insulating stainless steel pipework where the risk of CUI is a concern.

In addition to its superior thermal performance, Resolution Phenolic PPS delivers exceptional fire safety, achieving a Group 1S rating to ISO 9705 and full compliance with AS/NZS 1530.3 and AS 1366.2:1992 fire performance standards. These features ensure zero flame spread and negligible smoke development, making it a safe and dependable choice for the most demanding environments.

Accumen maintains ample stock of Resolution Phenolic PPS and can manufacture to order with exceptionally quick lead times, ensuring timely delivery to meet project requirements. No project is too large or too small, making Accumen a trusted partner for insulation needs across a wide range of applications.

Designed to meet diverse performance requirements, the product is available in various thicknesses and is compatible with mild steel, stainless steel, carbon steel, copper, and plastic pipework.

Thermal Performance

Accumen’s Resolution Phenolic PPS is engineered to deliver exceptional thermal efficiency, thanks to its low aged thermal conductivity. This characteristic makes it one of the most thermally efficient insulation materials commonly used in the market today.

Enhanced Energy Efficiency: The low thermal conductivity ensures minimal heat transfer, resulting in superior insulation performance. This significantly reduces energy loss in pipe systems, improving overall operational efficiency.

Space-Saving Design: A key advantage of the material’s low thermal conductivity is that it allows specified thermal performance standards to be achieved with much thinner insulation compared to other materials. This not only conserves space but also reduces the overall weight of the insulated system, simplifying installation and handling.

Long-Term Performance Stability: The aged thermal conductivity remains consistently low over time, ensuring sustained insulation performance throughout the product's lifecycle.

These attributes make Resolution Phenolic Pipe Insulation a preferred choice for applications where thermal efficiency, space constraints, and long-term reliability are critical.

Fire Performance

Resolution Phenolic PPS products are designed to deliver exceptional fire performance, ensuring safety and compliance across a wide range of applications.

Group 1S Rating (ISO 9705): These products achieve a Group 1S classification, the highest possible rating for fire performance under the ISO 9705 Room Corner Test. This rating demonstrates excellent resistance to flame spread and very low smoke production, making them suitable for use in critical environments where fire safety is paramount.

Compliance with AS/NZS 1530.3: Resolution Phenolic products easily meet the stringent requirements of the AS/NZS 1530.3 standard, which assesses materials for:

- Ignitability: Minimal tendency to ignite.

- Spread of Flame: Extremely low spread, reducing fire propagation risks.

- Heat Evolved: Low heat release during exposure to fire.

- Smoke Developed: Minimal smoke generation, ensuring visibility and safety in the event of a fire.

These attributes, combined with its exceptional thermal insulation properties, make Resolution Phenolic Pipe Insulation an outstanding choice for projects that prioritize fire safety alongside energy efficiency.

Environmental

Resolution Phenolic PPS stands out as an environmentally responsible insulation solution due to its impressive sustainability attributes. The manufacturing process utilises a blowing agent that is entirely free of CFCs and HCFCs, substances known to deplete the ozone layer. This ensures the foam achieves a zero Ozone Depletion Potential (ODP), making it a safer choice for the environment compared to traditional insulation materials.

In addition, Resolution Phenolic PPS boasts a low Global Warming Potential (GWP), meaning its overall contribution to greenhouse gas emissions during production and use is significantly minimized. This aligns with global efforts to combat climate change by reducing the carbon footprint associated with building materials.

Beyond its manufacturing process, the foam's closed-cell, fibre-free structure enhances its thermal efficiency and durability, eliminating issues such as air infiltration. By preventing thermal bridging and maintaining consistent insulation performance over time, it contributes to long-term energy savings, further reducing environmental impact by decreasing the energy demands of heating and cooling systems.

These attributes collectively position Resolution Phenolic PPS as a sustainable choice for environmentally conscious construction and industrial applications.

Moisture

Resolution Phenolic PPS features a 95% or greater closed-cell structure, which plays a critical role in its superior performance. This high closed-cell content ensures the material is non-wicking, meaning it resists absorbing water even in high-moisture environments. This characteristic makes the insulation highly resistant to moisture penetration, a vital attribute for maintaining its thermal integrity and long-term performance.

In addition to its inherent resistance to moisture, Resolution Phenolic PPS is equipped with a factory-applied high-performance facing that serves as an advanced vapour barrier jacket. This facing provides an extra layer of protection against moisture ingress, ensuring the insulation system remains dry and effective throughout its lifespan. This dual-layer moisture defence system significantly reduces the risk of water absorption, which is a common challenge in many insulation systems.

By preventing moisture from entering, the insulation avoids issues such as reduced thermal performance, material degradation, and potential mold or mildew growth. These features make it an ideal solution for applications in environments where exposure to humidity, condensation, or water is a concern, such as HVAC systems, industrial piping, or chilled water systems.

With its combination of closed-cell structure and robust vapour barrier, Resolution Phenolic PPS ensures long-lasting durability, consistent thermal performance, and protection against environmental challenges, contributing to reduced maintenance costs and improved energy efficiency over time.

TDS (Technical Data Sheet) Resolution Phenolic PPS

SDS (Safety Data Sheet) - Resolution Phenolic Foam